We had already provided many pet bottle factories in Thailand, Spain, Nigeria and others. From PET raw material purchase to all water bottle equipment, we had ability to satisfy each step.

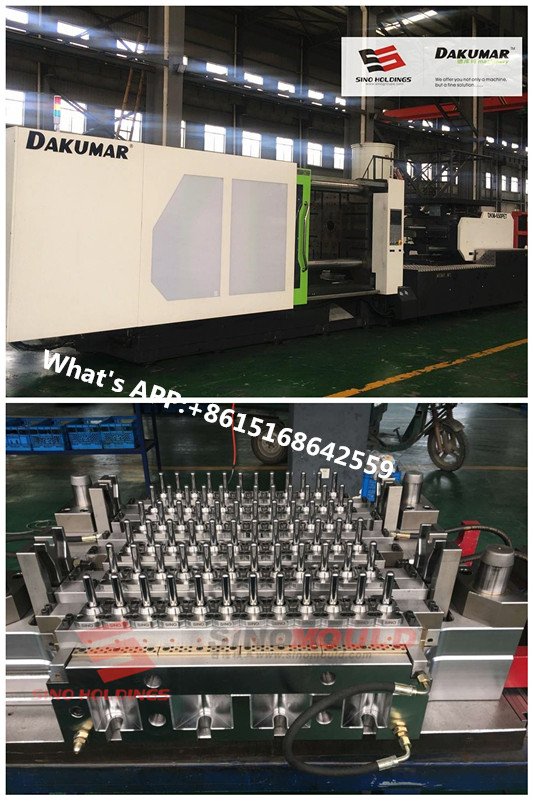

A complete pet water bottle lines contains PET raw material, PET injected mold, PET preform injection molding machine and related accessories, blow mold, blowing machine and filling machines. Below simple introduce our 72 cavities injection pet water line.

Preform is PCO 28mm water 0.5L, gram is about 16g. Since customer per hour capacity need reach about 12,000 pieces, we design preform mold with 72 cavities. And use S136 steel for cavity and core,P20 for mold base. Besides, preform design need special attention on cooling system and air venting system. With rich experience, our team had finished and were successfully proved by actual production operation.

After preform mold finishing, PET injection molding machine is also a main role in water bottle line. Moulding machine requires high plasticization, high gram weight per shot, and stability operation and easy for maintenance. Besides, other accessories like water chiller, dehumidification and dryer machine and so on, this will greatly improve cycle time.

More information regarding to pet bottle factory, pls feel free to contact me.

From : Stacy

Email: sino6001@dakumar.com sino6001@sinomould.com

Skype: sinogroupe-62

What’s APP: +8615168642559

Tag: plastic injection machine injection machine maker plastic machine manufacturer